About

Services

Projects

Contact Us

Request Quote

Our Services.

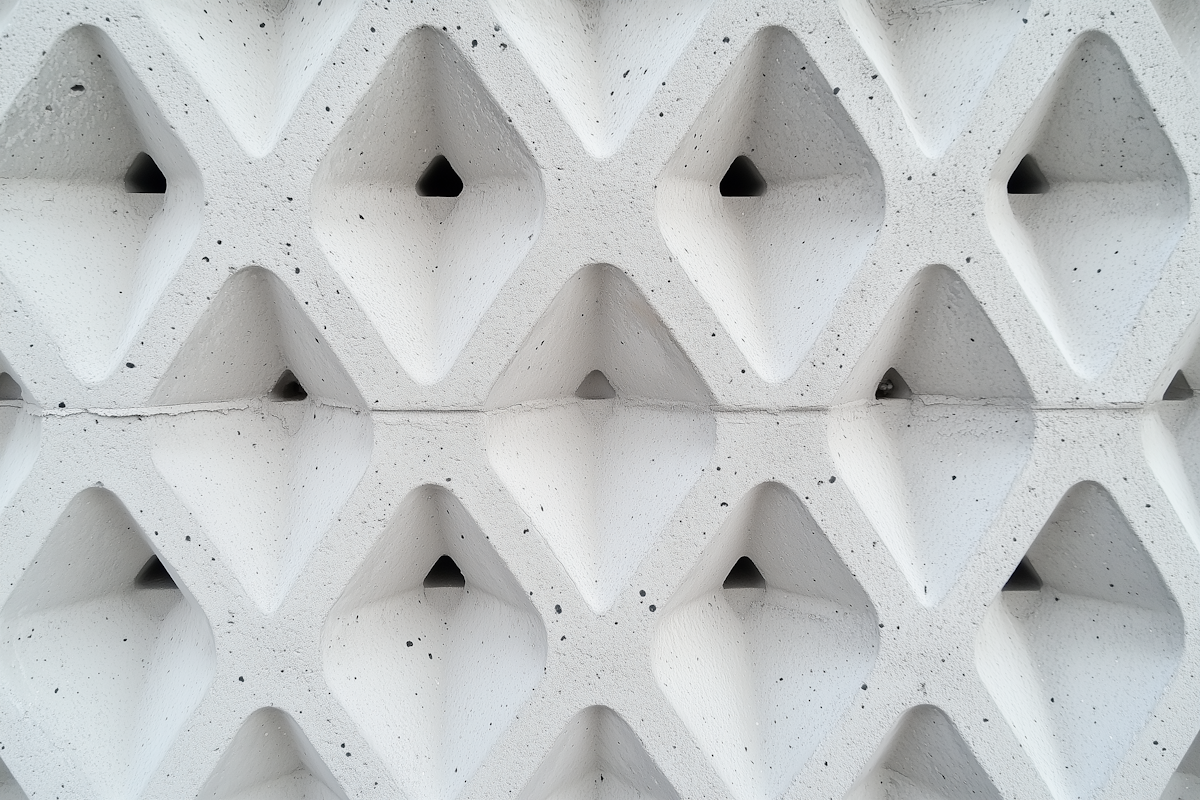

Specialists in the installation & finishing of concrete precast elements

Our Services

Here’s what we offer

Our team has been involved in the industry with over 20 years of experience operating primarily in the City of Melbourne installing concrete precast elements in every shape, size and form. We specialise in working with mobile cranes and tower cranes in the commercial and residential industry and are committed to ensuring and providing an efficient and high quality service with the installation of concrete panels, columns and elements.

Ready to get started?

Have a chat with one of our team today.

Contact Us

Our Services

Here’s what we offer

Our team has been involved in the industry with over 20 years of experience operating primarily in the City of Melbourne installing concrete precast elements in every shape, size and form. We specialise in working with mobile cranes and tower cranes in the commercial and residential industry and are committed to ensuring and providing an efficient and high quality service with the installation of concrete panels, columns and elements.

Ready to get started?

Have a chat with one of our team today.

Contact Us

CONTACT US

Our Services

Here’s what we offer

Our team has been involved in the industry with over 20 years of experience operating primarily in the City of Melbourne installing concrete precast elements in every shape, size and form. We specialise in working with mobile cranes and tower cranes in the commercial and residential industry and are committed to ensuring and providing an efficient and high quality service with the installation of concrete panels, columns and elements.

1

Installation of Precast

Professional installation of factory‑cast concrete panels, beams, columns (precast elements) onto prepared site foundations using cranes and specialised rigging. Includes precise alignment, temporary propping, anchoring, and coordination of lifting sequences to ensure safety and structural accuracy.

2

Rigging

Full rigging support including certified riggers and dog men to manage lifting equipment (slings, spreader beams, rigging hardware), ensuring safe hoisting and placement of precast elements. This service orchestrates crane operations in complete compliance with site safety.

3

Welding

On-site steelwork welding—commonly fillet-welding cast-in plates or embedded lifting studs—to connect adjacent panels or structural elements securely. Adds rigidity to joints and overall structure to resist loads such as wind.

4

Grouting

Application of grout between panel joints and beneath base plates to create a continuous structural load path, eliminate voids, and waterproof connections. Often uses non‑shrink grout to ensure tight, durable fills.

5

Caulking

Sealing of panel-to-panel junctions, window/door openings, façade lines using high-quality sealants (e.g. polyurethane, silicone, fire‑/acoustic-rated types) to seal against air and water infiltration and to accommodate movement.

6

Patching

Repairing minor surface damage such as chips, stitching plate areas, lifting inserts or weld joints. Uses high-build or lightweight mortars and coatings to restore finish and weather protection post-installation.

Ready to get started?

Have a chat with one of our team today.

Contact Us

CONTACT US